As the external covering of a product, the product shell not only plays an important role in protecting the internal structure and components of the product but also directly reflects the image of the product. Therefore, it is crucial to design a scientifically reasonable, practical, and aesthetic product shell. The following will discuss several key aspects of product shell design in detail.

- Material Selection

The choice of shell material directly affects the appearance, performance, and service life of the product. In OPD design, designers need to select appropriate materials based on factors such as product positioning, use environment, and cost budget. For example, metal or alloy materials are good choices for products that require high strength and wear resistance; while plastic or composite materials are more suitable for products that need to be lightweight and easy to process. At the same time, with the increasing awareness of environmental protection, choosing recyclable and biodegradable environmentally friendly materials is also an important consideration.

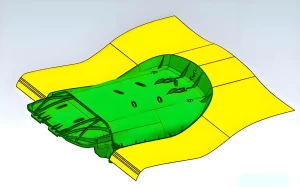

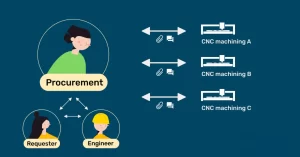

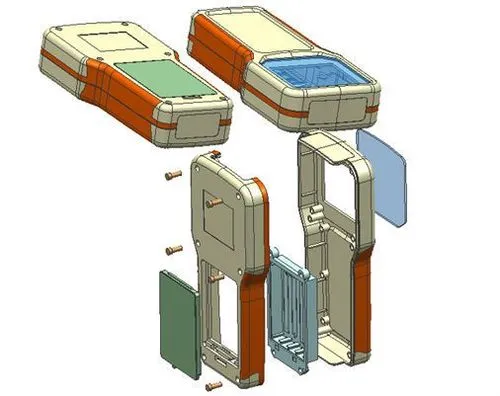

- Structural Design

Structural design is the core of product shell design. Designers need to comprehensively consider factors such as the product’s functional requirements, structural strength, heat dissipation performance, and maintenance convenience to design a shell structure that meets both aesthetic and practical requirements. For example, the strength and stiffness of the shell can be improved through reasonable rib design; the heat dissipation performance of the product can be enhanced by optimizing the layout of the heat dissipation holes; and modular design can facilitate subsequent maintenance and upgrades. The Power of Prototyping plays a crucial role in testing these design elements before final production.

- Appearance Design

Appearance design is an important part of product shell design. Designers need to design an appearance that is unique and attractive based on the characteristics of the product and market demand. This includes color matching, line design, texture processing, and other aspects. At the same time, designers also need to pay attention to the overall style of the product and ensure that the shell design coordinates with the internal structure and functions of the product.

- User Experience

User experience is an aspect that cannot be ignored in product shell design. Designers need to focus on the user’s feelings and needs during the product usage process and improve user comfort and convenience by optimizing the shell design. For example, adding anti-slip design can prevent users from slipping during use; optimizing the button layout can improve user operation efficiency; and considering different users’ habits, designers also need to design shell structures with universality.

- Sustainability

Sustainability is an important consideration in product shell design. Designers need to choose environmentally friendly materials, reduce energy consumption and emissions during production, and design shells that are easy to recycle and reuse. This not only helps to reduce the impact of the product on the environment but also enhances the company’s social image and sustainability.

In summary, product shell design is a comprehensive process that requires consideration of multiple aspects such as material selection, structural design, appearance design, user experience, and sustainability. Designers must innovate to create practical and aesthetic product shells that meet market demands, especially for All Electronics Made in China, where quality and design are crucial.