The Split Line in Plastic Part Design: More Than Just a Cosmetic Detail

If you look closely at almost any plastic product around you – your phone, remote control, or kitchen appliance – you’ll notice subtle lines grooved

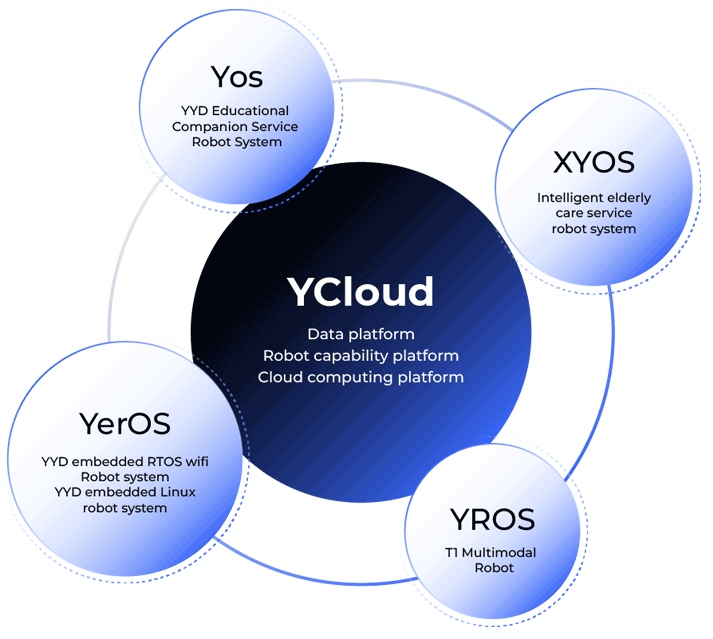

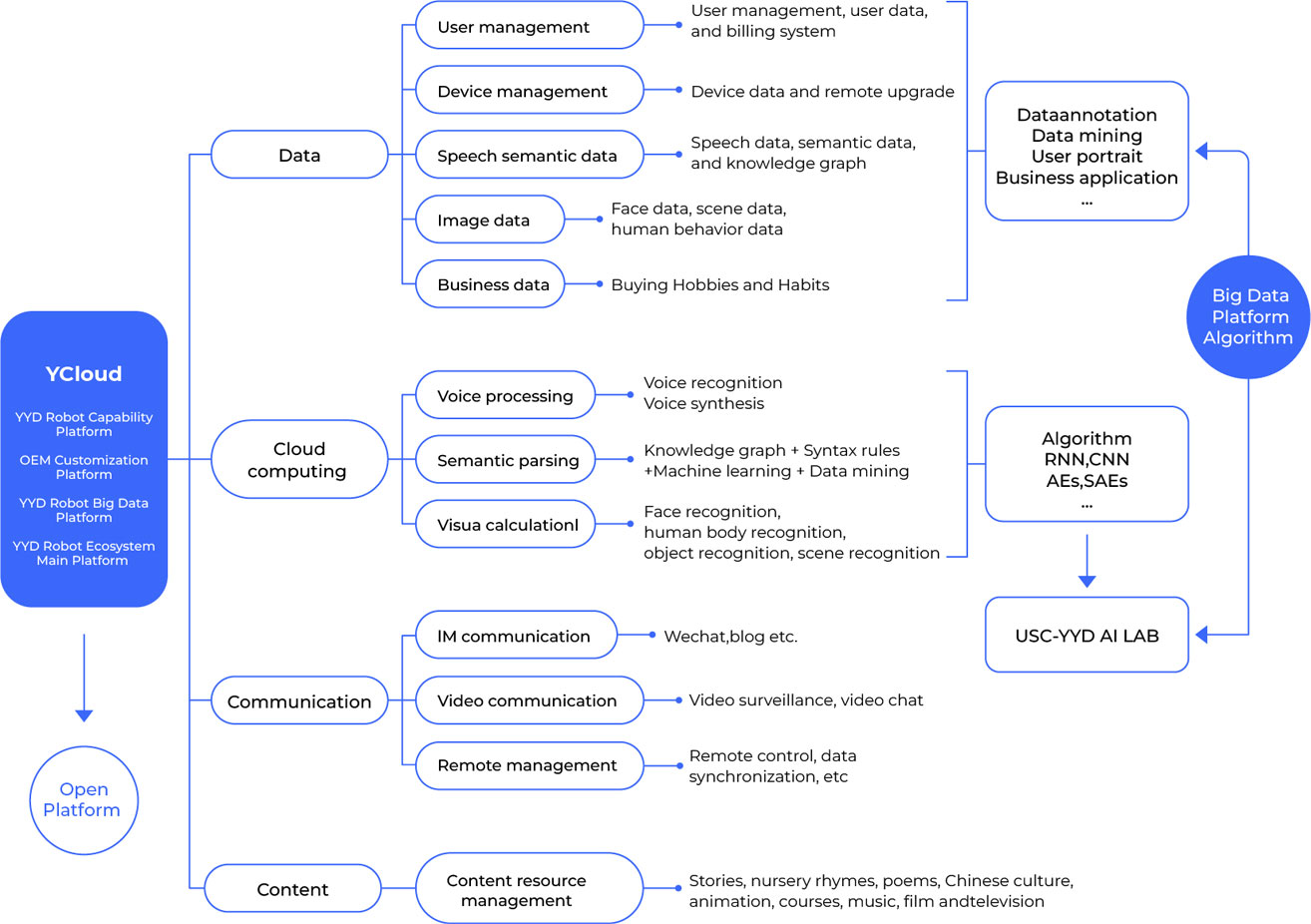

OPD and it spartner shave collaboratively established acomprehensive AI industryecosystem. This ecosystemen compassesadvanced technology in three pivotal areas: NLP/GPT, computer vision (CV), and autonomous navi-gation and walking (SLAM). With many yeasrs of technological experience, OPD hassecured more than 200 independent intellectual property rights.

OPD and it spartner shave collaboratively established acomprehensive AI industryecosystem. This ecosystemen compassesadvanced technology in three pivotal areas: NLP/GPT, computer vision (CV), and autonomous navi-gation and walking (SLAM). With many yeasrs of technological experience, OPD hassecured more than 200 independent intellectual property rights.

The ecosystem supports acomplete system for researchand development, production, sales and service. Moreover, OPD possessesfull productionand manufacturing capabilities across the entireindustry chain.The secapabilities include solution design, moldmaking,injection molding, spraying, assembly,and testing.OPDhas also forged deep partnerships with numerous renowned com-panies both domestically and internationally. Additionally, theyhave developed a big data platform that has been operational forsevenyears, providing over 3 billion services to users to date.

(Natural Language Processing)

(Image semantic understanding and object grasping )

( Localization and Mapping)

Located in the National High-tech Development Zone of Heyuan City, Guangdong Province, the park covers an area of 100,000 square meters. It specializes in providing one-stop services for the development and design of intelligent hardware products. mold design and production, injection molding and spraying, electronic finished product assembly and testing, quality management and after-sales, The products involved include robots, smart wearables, smart speakers, smart homes and communication equipment.

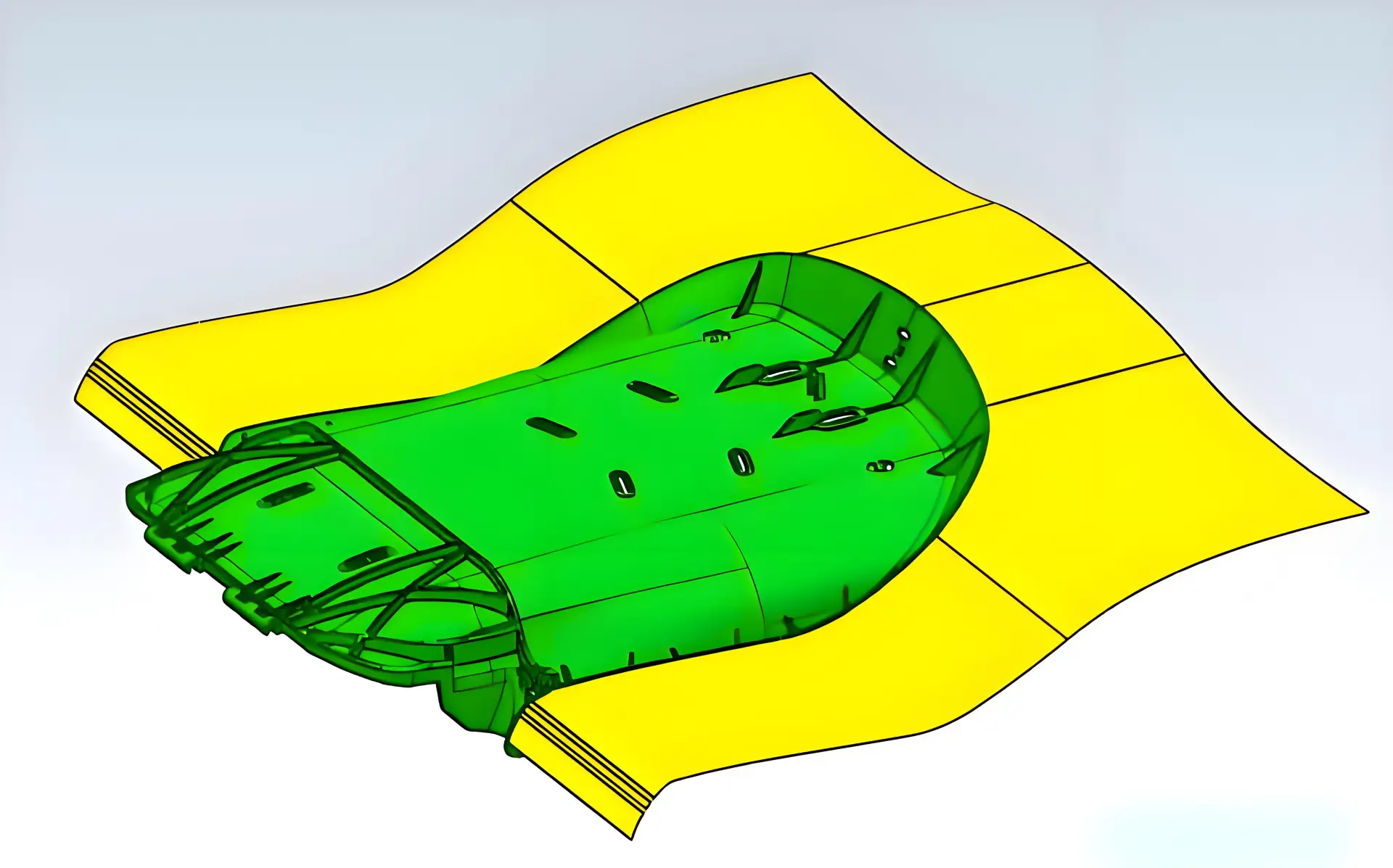

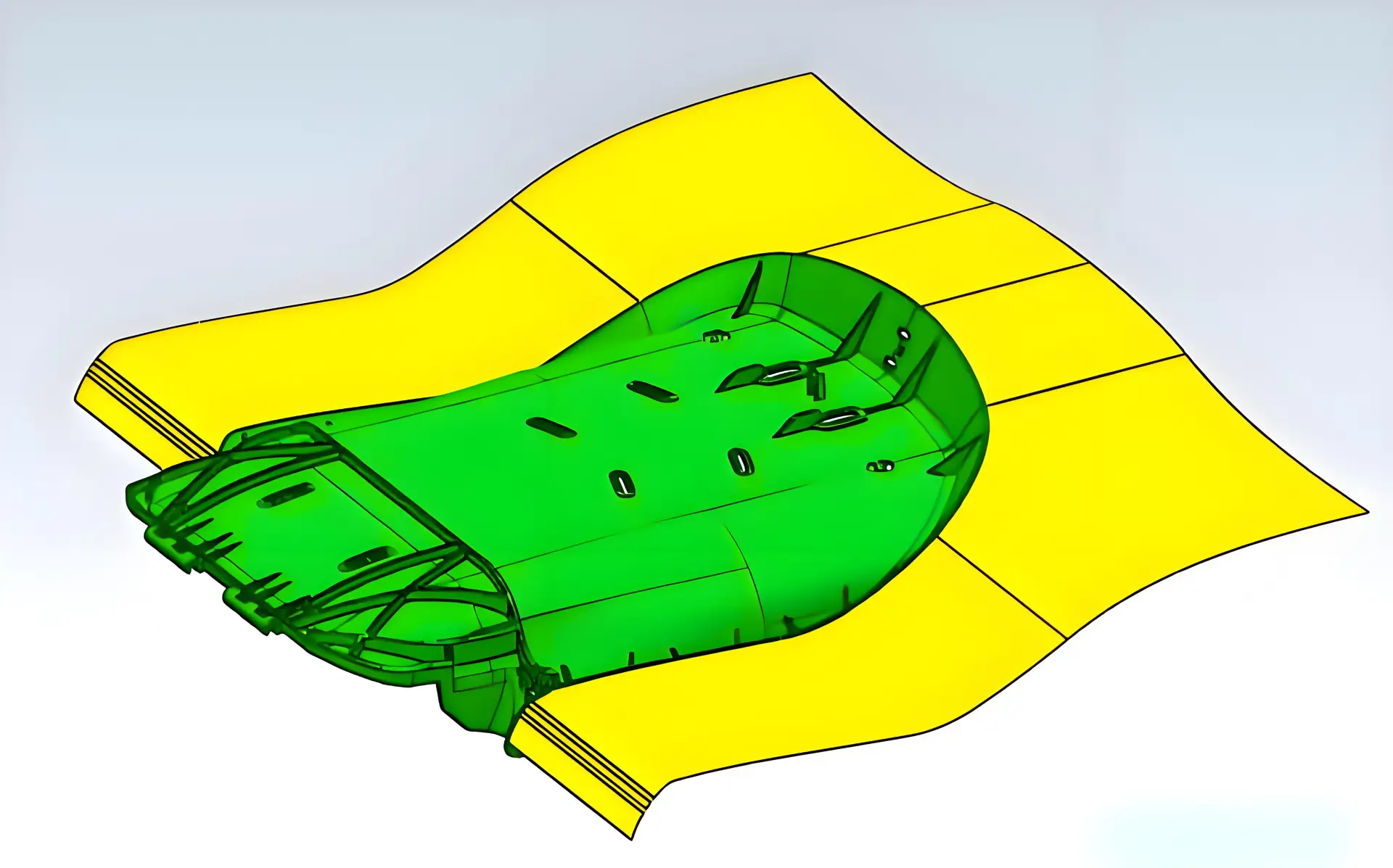

Our prototype center boasts advanced equipment, including 3D printers, CNC machines, and vacuum molding machines. With more than 20 seasoned professionals on our team, we specialize in creating plastic prototypes, metal prototypes, and various other types. Leveraging our exquisite craftsmanship and efficient services, we deliver precise prototype solutions to expedite product development and market introduction.

Mold workshop is equipped with state-of-the-art processing equipment, including high-precision CNC machine tools and EDM machines. Our professional team consists of over 40 highly skilled members, specializing in the manufacture of injection molds and die-casting molds. These molds are extensively utilized in various sectors such as automotive, electronics, and home appliances.

Main Equipment:

• CNC Spark Machines (SODICK, etc.)

• CNC Slow Wire (SODICK)

• CNC High-Speed CNC (DMG, MAKINO)

Our injection molding workshop is equipped with numerous advanced injection molding machines of various specifications, capable of accommodating a wide range of product sizes. The workshop features professional mold installation and debugging equipment, alongside an automated material conveying system. Our dedicated technical team, comprising 60 skilled professionals, rigorously oversees the production process to ensure the highest quality of each injection molding product.

Key Features:

The spraying workshop is designed as a 10,000-level dust-free environment. Our main production process utilizes a fully automated two-coat and two-bake spraying technique. The automatic line is equipped with high-quality spray gun equipment and high-energy UV light curing equipment.

Key Features:

Our company currently operates two 100,000-level dust-free assembly workshops and seven bidirectional assembly lines, all housed within a newly constructed four-story supporting factory building, totaling 16,000m². This infrastructure is designed to meet the increasing demand for orders.

Key Features:

Each robot product we manufacture undergoes rigorous testing to ensure reliable product quality. Our testing laboratory is equipped with a comprehensive range of advanced equipment to perform various assessments.

Testing Equipment:

If you look closely at almost any plastic product around you – your phone, remote control, or kitchen appliance – you’ll notice subtle lines grooved

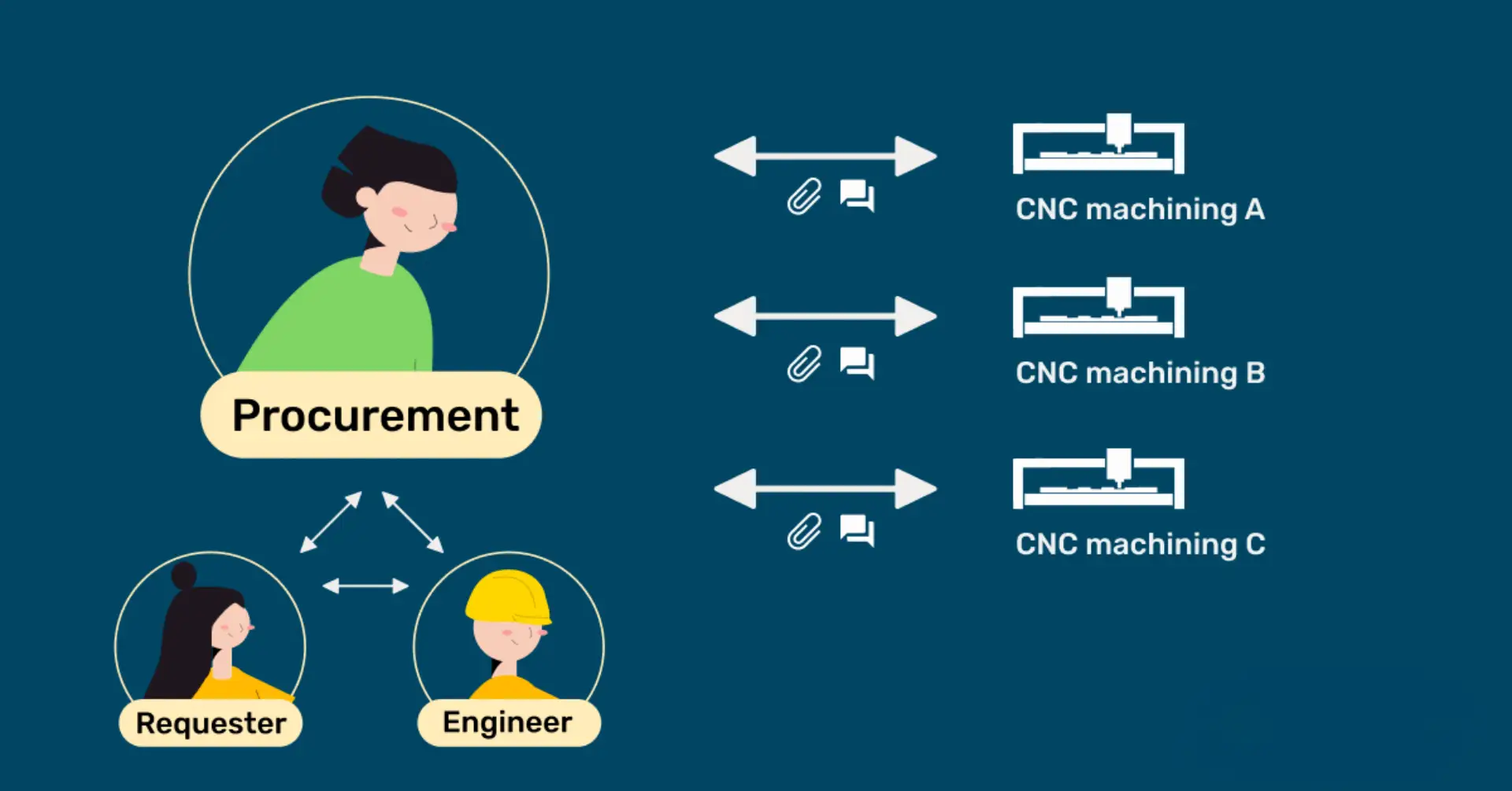

Transforming Cost Centers into Value Architects In today’s hypercompetitive markets, isolating procurement until design finalization risks locking in 70% of product costs prematurely while forfeiting

Decoding the systematic creativity behind China’s $1.6B toy empire 1. The Engine of IP Creation: Standardized Yet Flexible Design Workflow 1.1 Bridging Artistry and Industrialization