In the world of product design and development, “prototyping” is a critical concept that plays a key role in turning ideas into reality. Whether you are an engineer, designer, or entrepreneur, understanding what a prototype is, why it is needed, and how to use it effectively can significantly impact the success of your hardware project. This article aims to explain the term “prototype,” explore its various forms, benefits, and best practices in hardware product development.

What is a Prototype?

A prototype is an early sample, model, or release of a product used to test a concept or process. In the hardware domain, a prototype is a physical representation of the final product, designed to validate the design, functionality, and usability to ensure all necessary requirements and specifications are met before mass production. It serves as a tangible tool for testing, refining, and validating ideas, ensuring the final product meets all necessary requirements and specifications.

Why Use Prototypes?

The primary purpose of creating a prototype is to test and refine ideas without investing significant time and resources into full-scale production. Here are some benefits of incorporating prototypes into your hardware development workflow:

- Cost and Time Savings: By identifying potential issues early, teams can make adjustments before moving forward, saving both time and resources.

- Improved Product Quality: Prototypes allow for thorough testing and validation of designs, ensuring the final product is reliable, functional, and user-friendly.

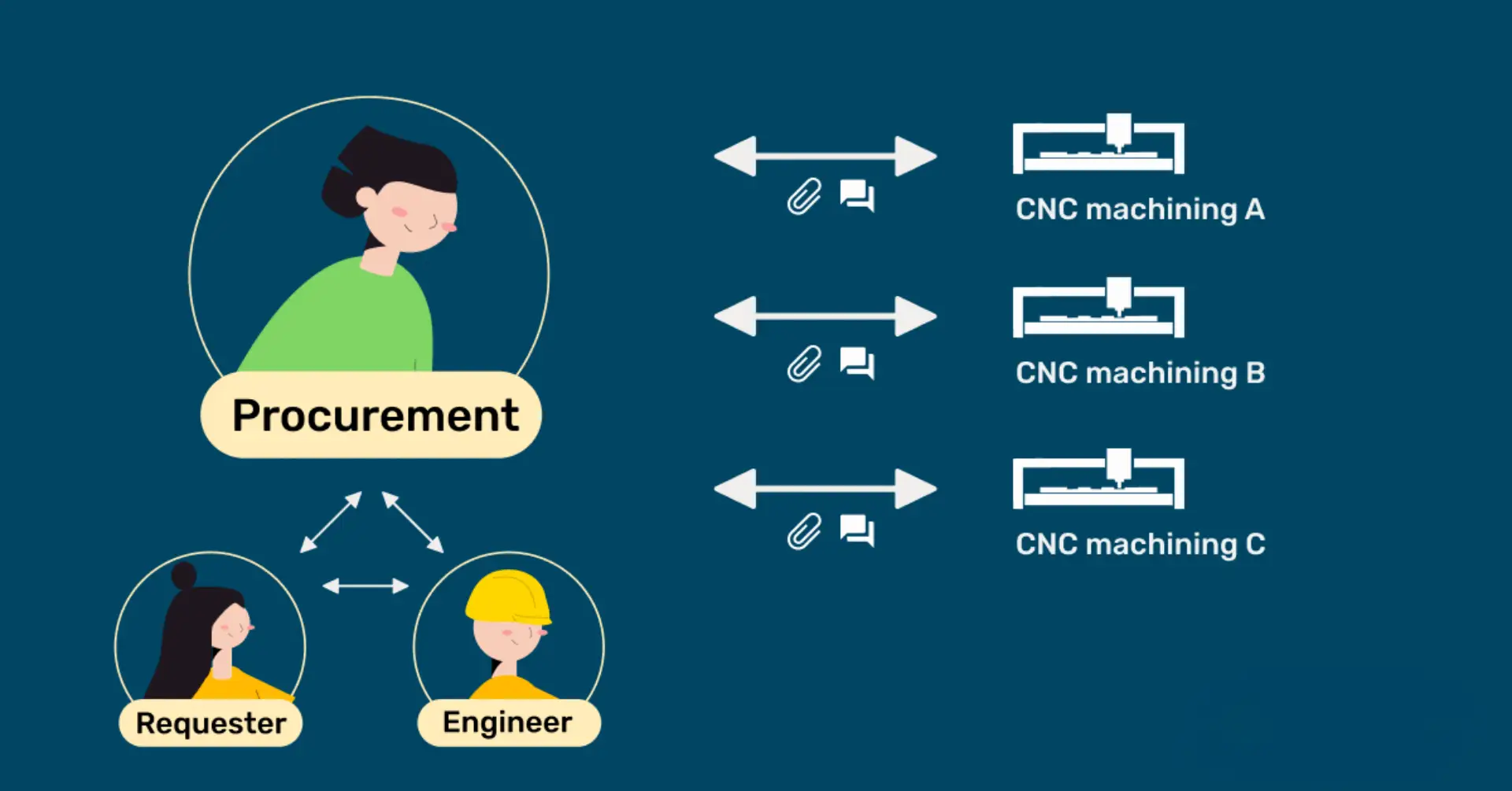

- Enhanced Communication and Collaboration: Physical models help bridge communication gaps between team members, stakeholders, and customers, aligning everyone toward a common goal.

- Increased Innovation: The freedom to explore and iterate encourages creativity, leading to more innovative solutions.

Types of Hardware Prototypes

Hardware prototypes come in various forms, each serving different purposes depending on the stage and specific needs of the project.

1. Proof of Concept (PoC) Prototype

- Purpose: To demonstrate the feasibility of a basic idea or concept.

- Characteristics: Simple, often made with off-the-shelf materials, may not be fully functional.

- Use Case: Early-stage testing to validate core concepts.

2. Form Study Prototype

- Purpose: To evaluate the physical shape, size, and ergonomics of the product.

- Characteristics: Focuses on external appearance and user interaction, typically non-functional.

- Use Case: Design and ergonomic testing.

3. Functional Prototype

- Purpose: To test the functionality and performance of the product.

- Characteristics: Fully or partially functional, usually made with materials and components similar to the final product.

- Use Case: Testing and validating the technical aspects of the design.

4. Pre-Production Prototype

- Purpose: To simulate the final product as closely as possible.

- Characteristics: Highly detailed, made with the same materials and manufacturing processes as the final product.

- Use Case: Final testing and validation before mass production.

Methods of Creating Prototypes

Creating hardware prototypes involves various methods, each with its own advantages and limitations. Here are some common methods:

1. Handmade

- Description: Using manual tools and techniques to create the prototype.

- Advantages: Low cost, flexible, and suitable for simple designs.

- Disadvantages: Limited precision and difficult to scale.

- Tools: Manual tools, basic workshop equipment.

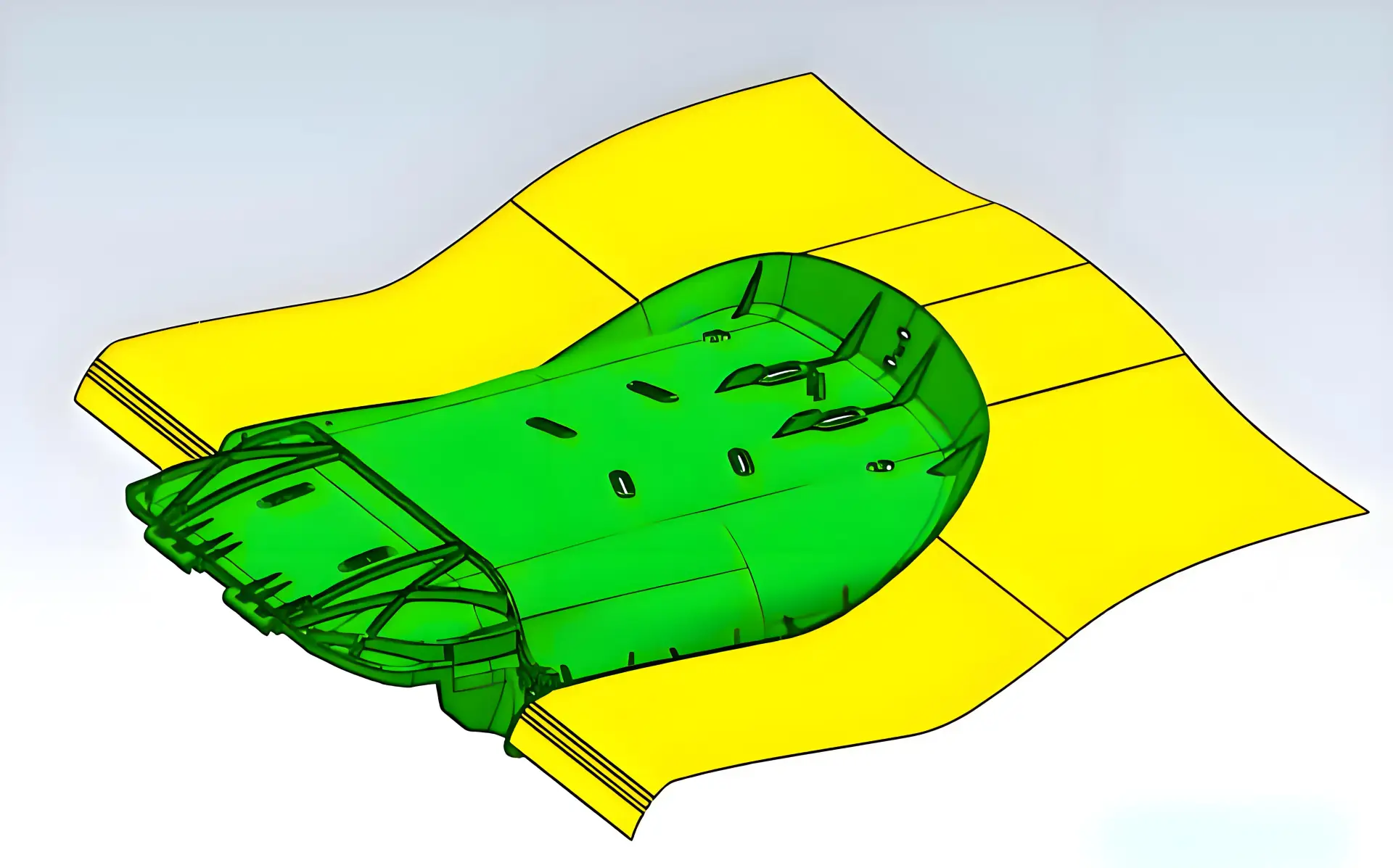

2. 3D Printing

- Description: Building the prototype layer by layer using additive manufacturing technology.

- Advantages: High precision, quick turnaround, and capable of creating complex geometries.

- Disadvantages: Limited material options and lower strength.

- Tools: 3D printer, CAD software.

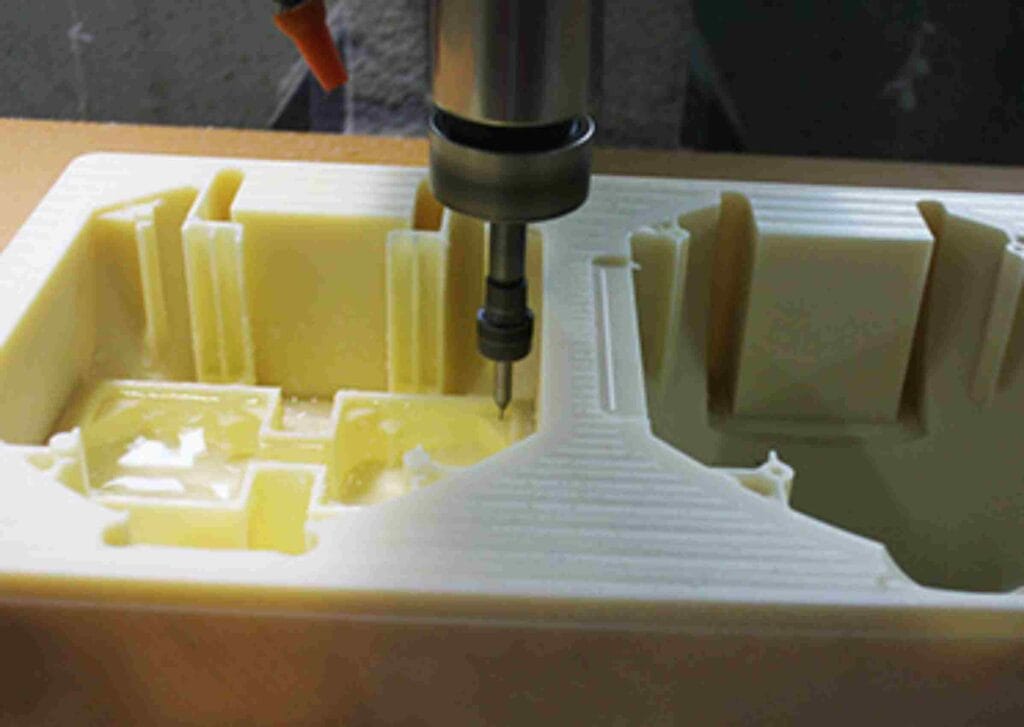

3. CNC Machining

- Description: Using computer-controlled machines to cut, drill, and shape the prototype from solid material blocks.

- Advantages: High precision, durable, and wide range of material options.

- Disadvantages: More expensive and time-consuming than 3D printing.

- Tools: CNC machine, CAD/CAM software.

4. Injection Molding

- Description: Injecting molten material into a mold to create the prototype.

- Advantages: High quality, consistency, and suitable for high-volume production.

- Disadvantages: High mold costs and long lead times.

- Tools: Injection molding machine, molds.

5. Laser Cutting

- Description: Using a laser to cut and engrave the prototype from flat sheets of material.

- Advantages: High precision, fast, and cost-effective for 2D designs.

- Disadvantages: Limited to 2D shapes and limited material options.

- Tools: Laser cutter, CAD software.

Best Practices for Effective Prototyping

To maximize the effectiveness of prototyping, consider the following strategies:

- Define Clear Objectives: Before starting, clearly define what you hope to achieve with the prototype. Are you testing a specific feature, overall form, or something else?

- Choose the Right Prototype Type: Based on your objectives, choose the most appropriate type of prototype. Remember, the level of detail should match the purpose.

- Iterate Based on Feedback: Prototyping is an iterative process. Gather feedback from users and stakeholders, then make improvements and repeat until satisfied.

- Keep It Simple and Focused: Especially in the early stages, avoid getting bogged down in too many details. Focus on key aspects and expand as needed.

- Use the Right Tools: There are many tools available for creating prototypes, from handmade to advanced manufacturing technologies. Choose based on your skills, budget, and project requirements.

Conclusion

Incorporating prototyping as part of your hardware development strategy can lead to better products, more satisfied users, and a more efficient development process. By allowing for experimentation, learning, and iteration, prototypes play a crucial role in transforming abstract ideas into tangible results. As you start your next project, remember the importance of prototypes and how they can elevate your work.

Whether you are looking to improve your current development practices or simply interested in the latest trends in hardware design, understanding and utilizing prototypes is the right direction. For further reading and to stay up-to-date with the latest developments in prototyping and other technology-related topics, consider subscribing to our newsletter or regularly visiting our blog.

By following these guidelines and integrating prototyping practices into your workflow, you will not only enhance the quality of your projects but also stay at the forefront of technological advancements. Happy building!